Dust extraction and cleaning of production areas in the cement, glass and quarrying industries.

As with the glass industry, the extraction of minerals and production of cement are sectors in which the work environment is subject to high quantities of fine dust and highly regulated release to the atmosphere.

Our expertise

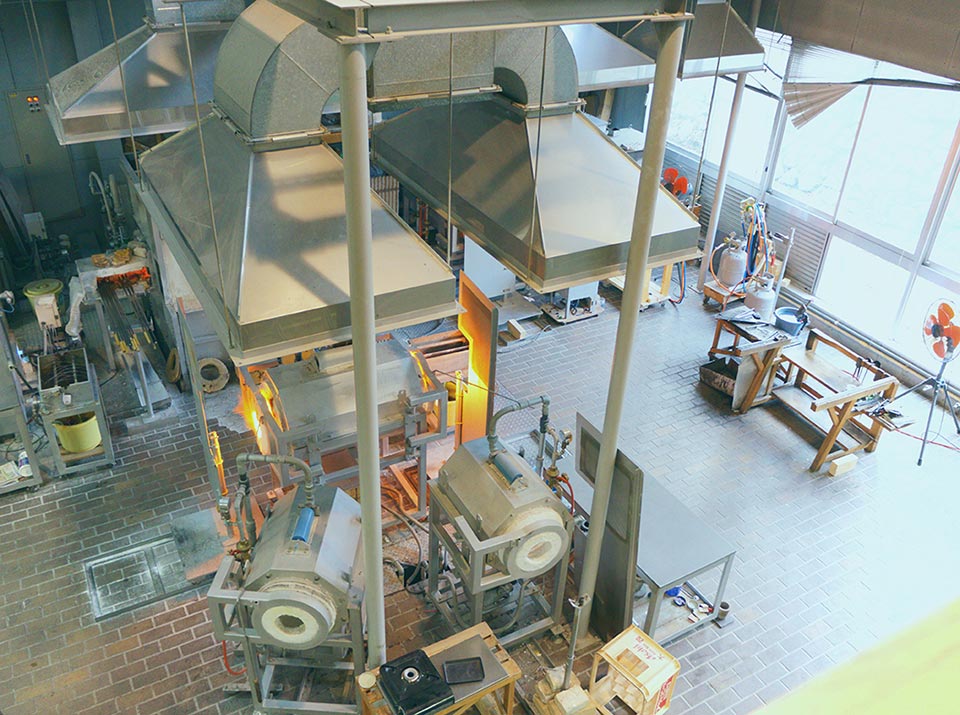

Handling equipment (unloading, handling, transfer, storage, bagging, etc.), and in particular processing equipment (crusher, grinder, screen, oven, coolant, etc.), generate pathogenic dust and fumes that can cause respiratory problems for operators, or even serious complications.

Suction of contaminants on these various processes, but also the cleaning of production areas (cleaning floors and machinery) improves the working conditions of operators and ensures that the products are manufactured in an ultra-clean environment.

A wide range of dust extraction equipment

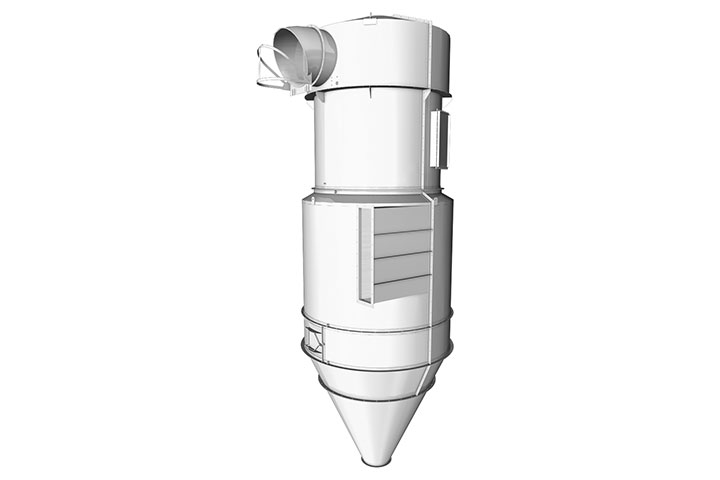

To address all of the problems faced by companies in the cement, glass and quarrying industries, CATTINAIR designs and offers a wide range of industrial dust extraction equipment, such as Cyclofilters, which complies with the ATEX Directive..

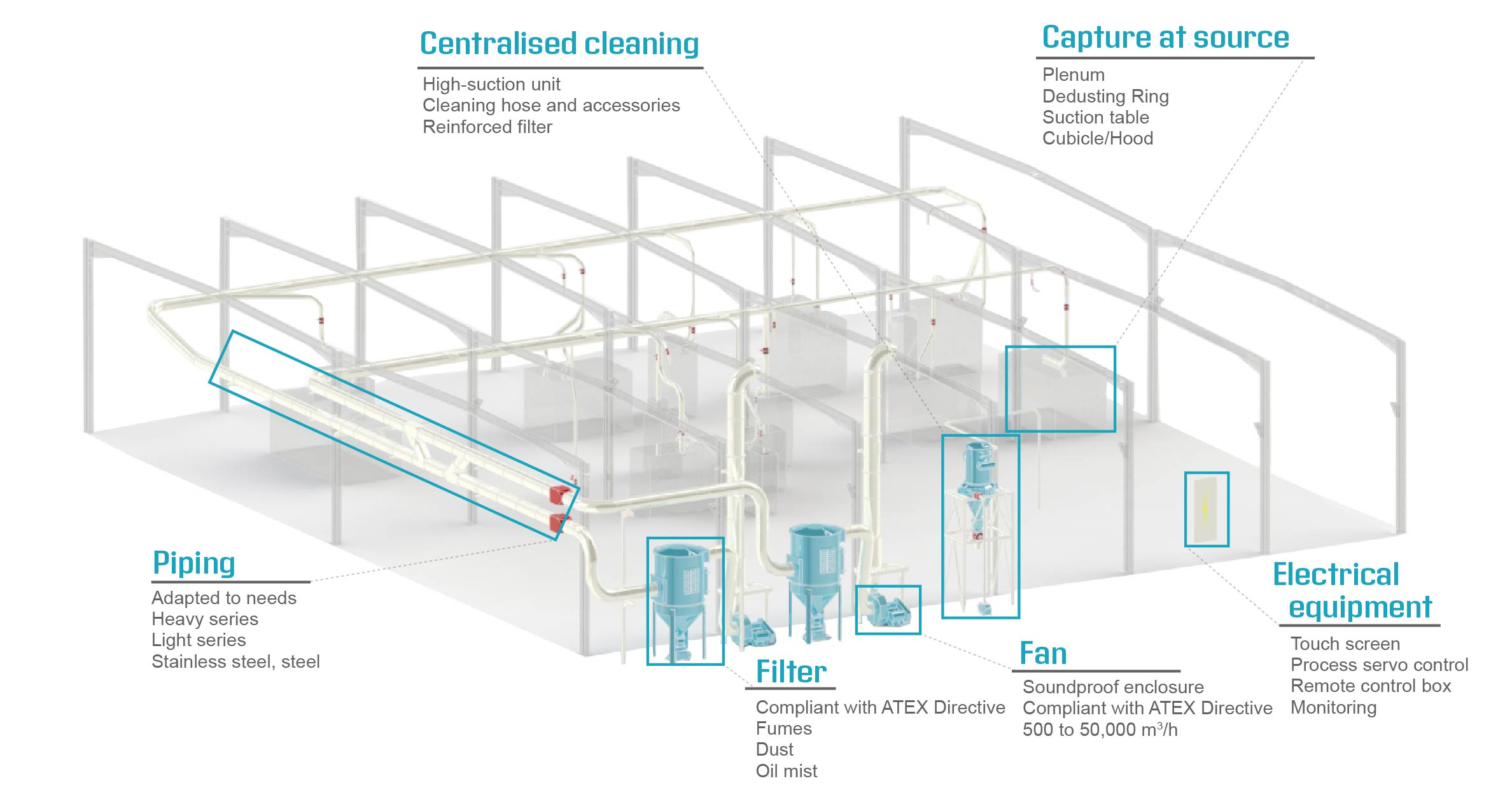

These dust extractors are installed to ensure continuous suction on production equipment, but they are also used to filter air from centralised cleaning installations (extraction unit).

Expert in “turnkey” engineering

The installation of industrial dust extraction, or sometimes ventilation, systems, is the way to address air quality issues within the cement, glass, quarrying, ceramics, brickworks and concrete products industries.

After a personalised and in-depth process study, our project managers develop specific, ergonomic dust extraction systems that capture contaminants at source: smelting fumes, mineral and chemical dust, oil mist, aerosols, etc.

For all mineral and chemical dust that has accumulated in and around the production tool. Our centralised vacuum extraction solutions capture the contaminants by means of cleaning accessories (suction attachments, brushes, pipes, etc.) connected to vacuum extraction hoses and outlets. The extraction points are installed directly in the workshop to enable the thorough cleaning of production areas and keep the industrial environment clean.

General ventilation systems can be used in addition to an extraction at source system and can remove any residual contaminants from a production area.

A comprehensive offer

Commissioning of installations by our project managers who helped design the installation.

Monitoring of proper functioning and measurement of air speeds and pressure losses of each machine and at different points of the suction collectors, motor intensities, as well as sound levels which are included in the technical file and certify compliance with the regulations.

Our Service Department offers original spare parts, upgrading and preventive maintenance contracts.

Are you an installer/fitter?

Regulations

Chemical products (in particular solvents) or dust of mineral origin (silica, asbestos, iron, zinc, cobalt, tin, etc.) provide numerous and varied routes of exposure in the workplace. This dust may come directly from the raw materials used (in powder form in particular) and are released during their production, transportation storage or implementation (extraction, crushing of mineral ores, flour production, manufacture and use of plastic materials, etc.).

They are also produced during the processing of finished or semi-finished products (metal machining, sawing, sanding, grinding of wood or synthetic materials, waster grinding…) or during demolition or cleaning operations. The occupational exposure limits apply to all forms of dust (marble, dust, etc.). Article R. 4222-10 of the French Labour Code.

8-hour time-weighted average

- total dust: = 10 mg/m3 of air

- respirable dust = 5 mg/m3 of air

Dust and chemical products can cause explosions. Solutions are available that reduce this risk and which must comply with the ATEX Directive.

More information available in our Regulations section.